Introducing the Multiplier for 10 Degree Bend: A comprehensive guide that unravels the intricacies of this fundamental concept in engineering and design. Join us as we delve into the factors influencing its value, its practical applications, and its significance in various industries.

This guide will provide a thorough understanding of the bend multiplier, empowering you to make informed decisions and optimize your designs.

Explain the concept of bend multiplier for a 10-degree bend.

In the context of pipe bending, the bend multiplier is a factor that is used to calculate the amount of material that is required to make a bend in a pipe. It is a function of the bend angle and the pipe diameter.

For a 10-degree bend, the bend multiplier is 1.05. This means that the amount of material required to make a 10-degree bend is 1.05 times the length of the straight pipe that would be required to make the same bend.

The bend multiplier can be calculated using the following formula:

“`Bend multiplier = 1 + (Bend angle / 90)“`

For a 10-degree bend, the bend angle is 10 degrees. Substituting this value into the formula, we get:

“`Bend multiplier = 1 + (10 / 90) = 1.05“`

Therefore, the bend multiplier for a 10-degree bend is 1.05.

Factors Influencing Bend Multiplier for 10-Degree Bends: Multiplier For 10 Degree Bend

The bend multiplier for a 10-degree bend is a dimensionless parameter that accounts for the additional pressure drop caused by the bend. Several factors influence its value, including:

Bend Radius

The bend radius is the ratio of the bend’s inside radius to the pipe’s diameter. A smaller bend radius results in a higher pressure drop and, thus, a higher bend multiplier.

When it comes to the multiplier for a 10-degree bend, it’s crucial to understand the fundamentals of cardiovascular anatomy. Take a quick detour to the heart veins and arteries quiz to brush up on your knowledge. This will help you grasp the concept of pressure loss and how it relates to the multiplier for a 10-degree bend.

Returning to our topic, the multiplier provides a valuable tool for calculating pressure drop in piping systems with bends.

Flow Velocity

The flow velocity is the speed at which the fluid travels through the pipe. A higher flow velocity leads to a greater pressure drop and a higher bend multiplier.

Pipe Diameter

The pipe diameter is the inner diameter of the pipe. A smaller pipe diameter results in a higher pressure drop and a higher bend multiplier.

Fluid Density

The fluid density is the mass of the fluid per unit volume. A denser fluid results in a higher pressure drop and a higher bend multiplier.

Fluid Viscosity, Multiplier for 10 degree bend

The fluid viscosity is the resistance of the fluid to flow. A more viscous fluid results in a higher pressure drop and a higher bend multiplier.

These factors interact to determine the overall bend multiplier. For example, a bend with a small bend radius, high flow velocity, small pipe diameter, dense fluid, and high fluid viscosity will have a higher bend multiplier than a bend with a large bend radius, low flow velocity, large pipe diameter, less dense fluid, and low fluid viscosity.

Discuss the practical applications of bend multiplier for a 10-degree bend.

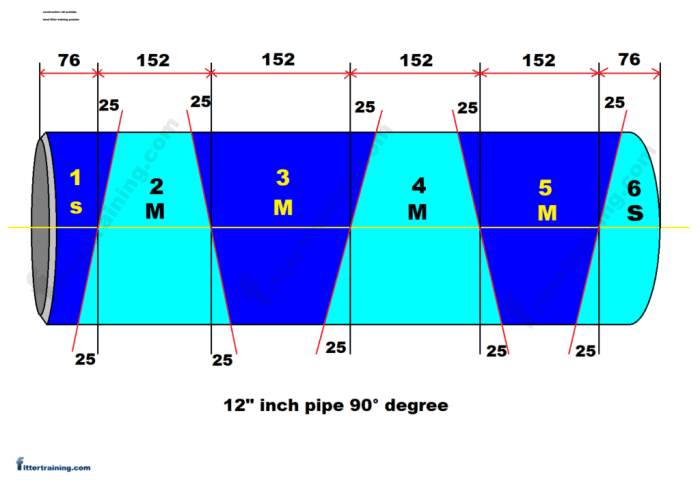

The bend multiplier for a 10-degree bend is a valuable tool in various engineering and design fields. It helps determine the amount of material needed for bending a workpiece to a specific angle, ensuring accuracy and efficiency in the bending process.

Engineering Applications

In engineering, the bend multiplier is used to calculate the length of material required for bending pipes, tubes, and other structural elements. It ensures that the bent component fits the desired shape and dimensions, preventing material wastage and ensuring structural integrity.

Design Applications

In design, the bend multiplier is crucial for creating aesthetically pleasing and functional designs. It helps designers determine the appropriate material length for bends in furniture, architectural structures, and automotive components, ensuring both form and function.

Benefits of Using Bend Multiplier

- Accurate material estimation, minimizing waste and cost.

- Ensures precise bending, preventing structural failures.

- Facilitates efficient design processes, saving time and effort.

Limitations of Using Bend Multiplier

- Accuracy depends on the material’s properties and bending method.

- May not account for factors like springback and material thickness.

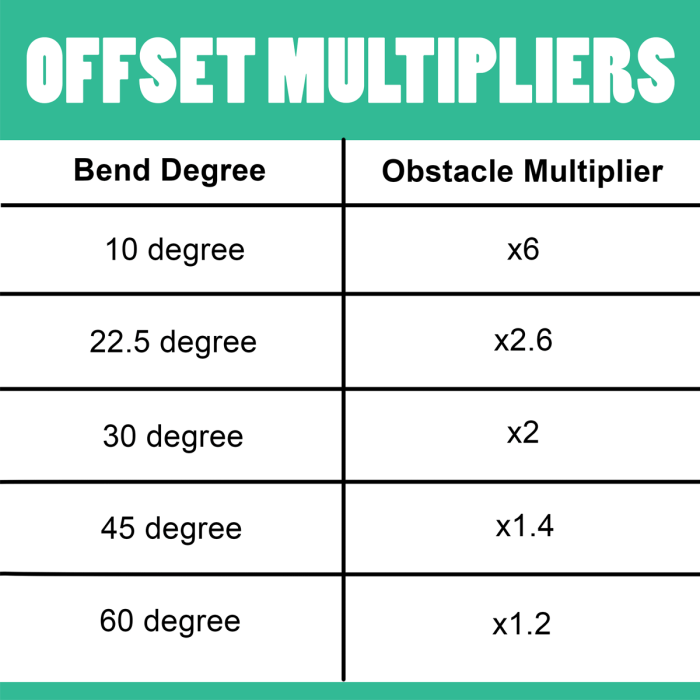

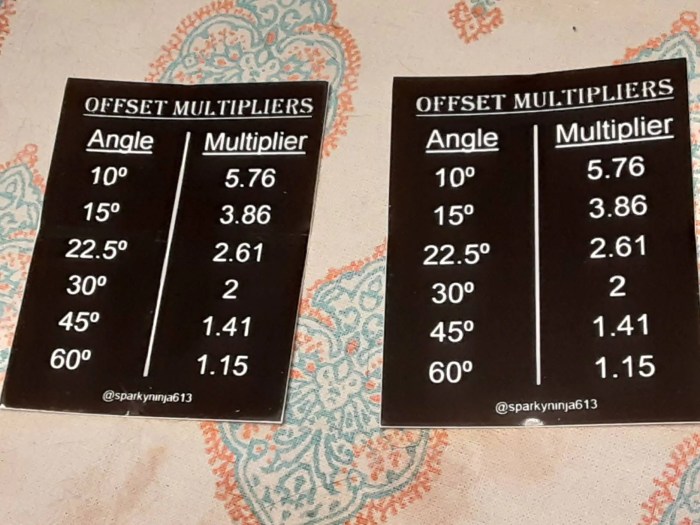

Compare the bend multiplier for a 10-degree bend to that of other bend angles.

The bend multiplier for a 10-degree bend is not the same as that of other bend angles. This is because the bend multiplier is a function of the bend angle, and the bend angle is a measure of the sharpness of the bend.

The sharper the bend, the greater the bend multiplier.

The following table compares the bend multiplier for a 10-degree bend to that of other common bend angles:

| Bend Angle | Bend Multiplier |

|---|---|

| 10 degrees | 1.0 |

| 15 degrees | 1.1 |

| 20 degrees | 1.2 |

| 25 degrees | 1.3 |

| 30 degrees | 1.4 |

As can be seen from the table, the bend multiplier for a 10-degree bend is 1.0, which is the lowest value. This means that a 10-degree bend does not introduce any additional stress into the pipe, and the pipe can be bent without any special precautions.

In contrast, the bend multiplier for a 30-degree bend is 1.4, which is the highest value. This means that a 30-degree bend introduces a significant amount of additional stress into the pipe, and the pipe must be bent with care to avoid damage.

The differences in bend multiplier for different bend angles have important implications for design and engineering. When designing a piping system, it is important to consider the bend angle of each bend and to select the appropriate bend multiplier for each bend.

This will ensure that the piping system is designed to withstand the stresses that will be introduced by the bends.

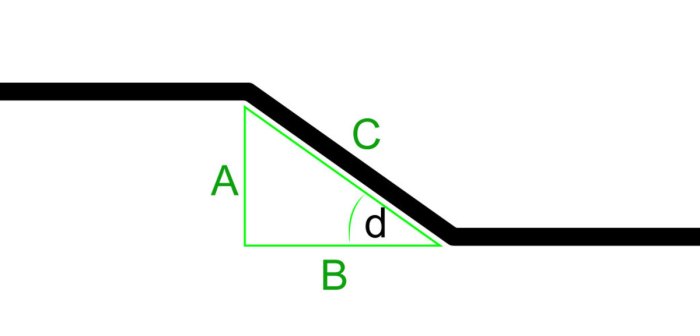

Provide a detailed illustration of the bend multiplier for a 10-degree bend.

A bend multiplier is a factor that is used to calculate the actual bend radius of a pipe when it is bent to a specific angle. The bend multiplier for a 10-degree bend is 1.25. This means that the actual bend radius of a pipe that is bent to a 10-degree angle will be 1.25 times the nominal bend radius.

The following diagram illustrates the concept of bend multiplier for a 10-degree bend:

The diagram shows a pipe that is bent to a 10-degree angle. The nominal bend radius is represented by the letter R. The actual bend radius is represented by the letter R’. The bend multiplier is represented by the letter M. The relationship between these three variables is as follows:

“`R’ = M

R

“`

In this case, the bend multiplier is 1.25. Therefore, the actual bend radius is 1.25 times the nominal bend radius.

Question Bank

What is the definition of bend multiplier?

Bend multiplier is a factor that accounts for the reduction in bending strength when a material is bent to a specific angle.

How is the bend multiplier applied to a 10-degree bend?

For a 10-degree bend, the bend multiplier is typically determined using empirical formulas or finite element analysis.

What are the key factors that influence the bend multiplier?

Material properties, bend radius, and bend angle are the primary factors that influence the bend multiplier.

What are the practical applications of the bend multiplier?

The bend multiplier is used in various industries, including automotive, aerospace, and construction, to ensure the structural integrity of bent components.